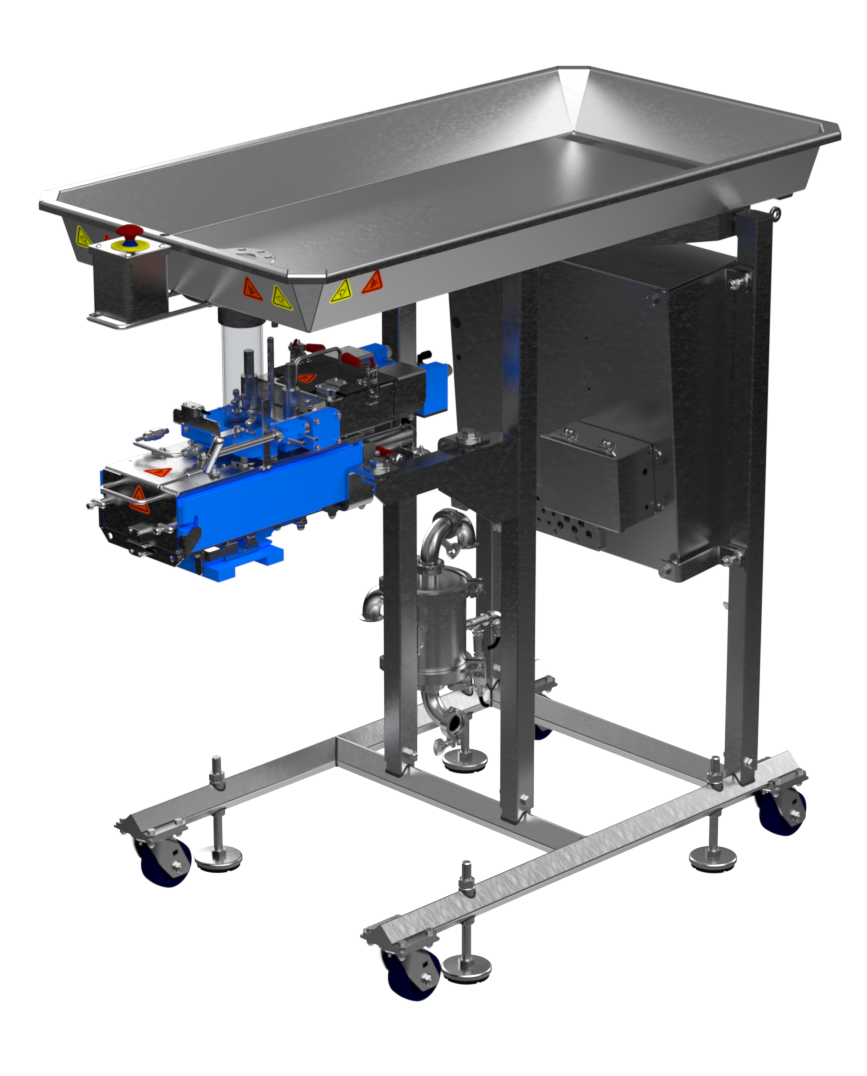

The MPFMP-060 volumetric pocket filler dispenses clean, accurate portions of a wide variety of difficult-to-fill products including:

- Cooked rice

- Cooked pasta (long & short)

- Cut vegetables & fruit

- Ready-to-eat salads

- Cereal

- Surimi, shrimp, & shredded meats

This filler is ideally suited for lower speed production lines, research and development labs, and pilot plant operations. It is rated at speeds up to 60 cpm, depending upon the product, volume to fill, container, line configuration, and operator.