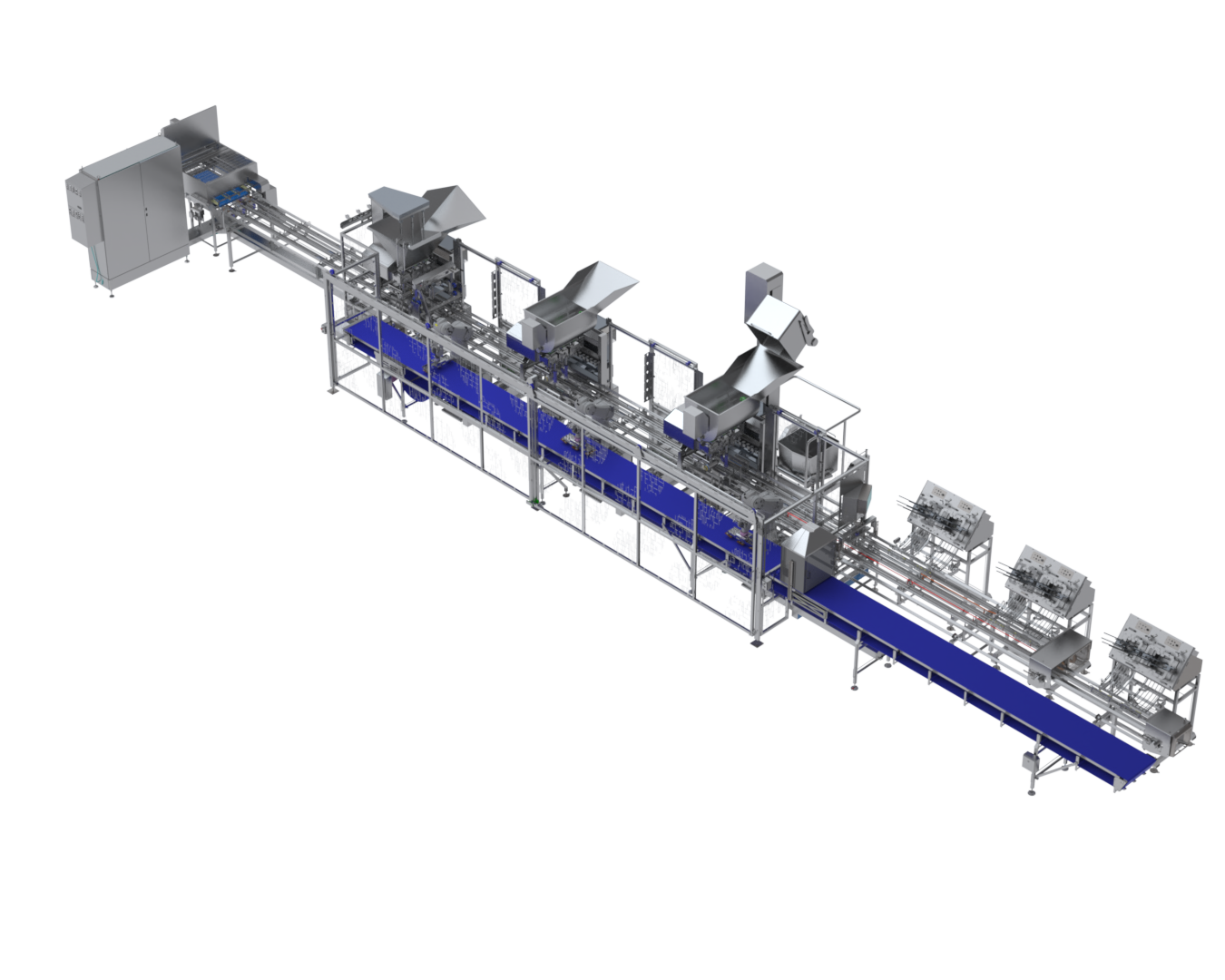

Lasagna Line

High-Efficiency Lasagna Production Line with Automated Dosing and Handling

Multi-Fill brings cutting-edge automation to lasagna production, offering precision dosing systems, hygienic robotic handling, and seamless integration to maximize efficiency and product quality.

Your Process

Tray Denester for Continuous Production

An automatic tray denester ensures a seamless start to the production process, feeding empty trays into the line without manual intervention.

- High-speed operation to match line throughput.

- Compatible with various tray sizes for flexible production.

- Designed for hygiene, preventing contamination in ready meal packaging.

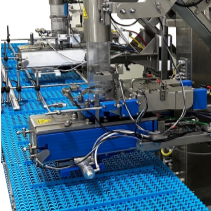

Precision Dosing for Meat Sauce & Béchamel

Our volumetric dosing systems ensure even and accurate layering of meat sauce and béchamel, guaranteeing consistent portioning for every tray.

- Handles various viscosities for perfect layering.

- Designed for hot or cold filling, adaptable to different recipes.

- Ensures no cross-contamination between ingredients.

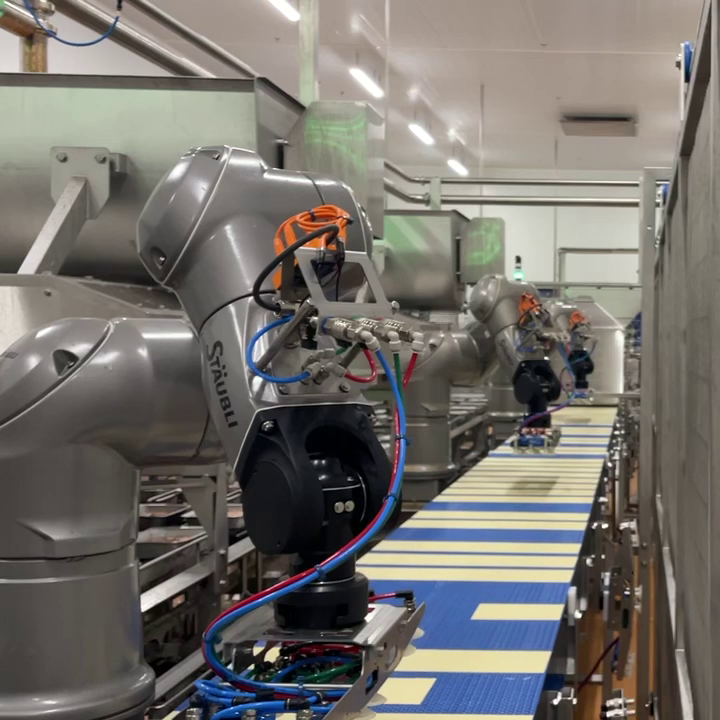

Hygienic Robotic Pasta Placement

Our food-grade robotic system ensures fast and accurate placement of lasagna sheets while maintaining strict hygiene standards.

- Non-contact handling for minimal contamination risk.

- Consistent alignment of pasta sheets for uniform layering.

- Washdown-compatible design for easy cleaning in food environments.

Oven Infeed

To optimize the loading and unloading of your furnaces, our conveyors can perform :

- Vision control

- Re-trimming by mechanical shovel or AIMTM technology: to ensure more homogeneous and densified filling

- Ejection of non-compliant products to a manual reclaim area

Cooling infeed

Our systems ensure optimum loading and unloading of your cooling spiral.

Our different technologies reorganize the number of products in continuous-flow bursts at the infeed and outfeed of the equipment.

At the same time, they provide the necessary re-drying to achieve the desired pasteurizing value.

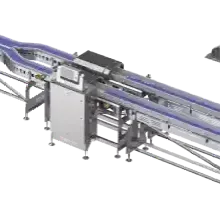

Buffering System for Smooth Workflow

Our buffering solutions maintain an uninterrupted flow between production stages, optimizing efficiency and preventing bottlenecks.

- Manages fluctuations in production speeds.

- Ensures a steady supply of trays for consistent output.

- Prevents downtime, maximizing overall line performance.

Flowpack or thermoformer feeder

A succession of conveyors brings the products to your packaging solution (thermoformer or flowpack).

Our conveyors can be synchronized with your packaging equipment for automatic filling.

Why Choose Multi-Fill?

End-to-End Automation

From tray unstacking to final layering, our solutions create a seamless, fully automated production process.

Flexible integration

Designed for mobility, our units can be quickly cleaned for product changeovers or moved to different production lines in minutes. They can be positioned over various conveying systems, whether continuous or intermittent, horizontal or vertical bagging machines.

Customizable & Scalable

We collaborate closely with your team to develop filling processes tailored to your specific requirements, ensuring seamless integration into your existing operations. Adaptable to different production capacities, from small-batch to high-speed industrial output.

Hygiene & Food Safety Focus

Designed with stainless steel, washdown-ready components, and food-safe robotics to meet industry standards.

Contact us Today

Ready to optimize your production line? Reach out to our team for expert advice and discover how Multi-Fill can elevate your operations.